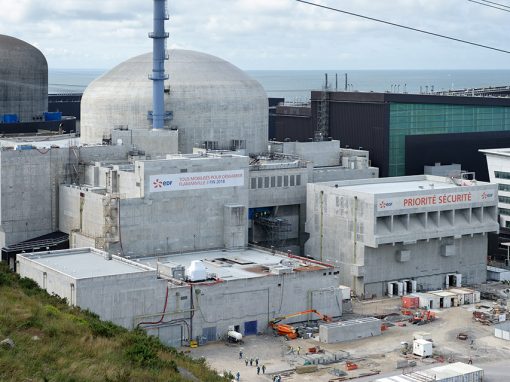

NUON 1200 MW ELECTRIC POWER PLANT

Client

MITSUBISHI

ROLE

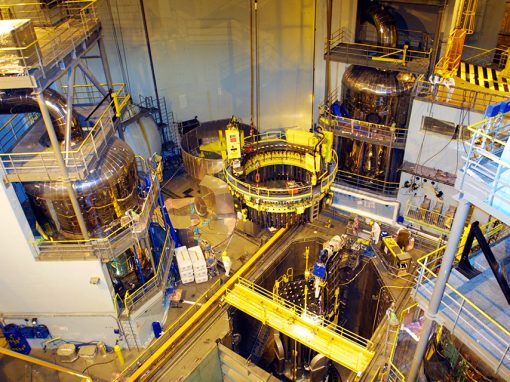

Part of the FIP consortium (Fabricom, Irem, Ponticelli) in charge of mechanical erection of: 3 x 400MW in gas combined cycle

LOCATION

EEMSHAVEN (THE NETHERLANDS)

DATE

2009/2012

CLIENT SPECIFICS

The schedule had to be respected in spite of bad weather conditions in northern Holland. The consortium intervened in closed buildings which were only accessible by a future maintenance access, a small trap making the transport of equipment critical. Another solution was needed.

PONTICELLI’S CHALLENGES

The challenge: bringing a large quantity of equipment to be installed in the factory plant became the project’s critical feature.

The solution: use the area reserved as an air inlet as the second transit gate.

To do so, Ponticelli decided to pre-install the Air Inlet module on the storage area, transfer and install it by heaving lifting once all the equipment had been delivered in the building, having previously asked the Air Inlet supplier to modify the equipment’s structure so that it was adapted to the operation.

The operation was repeated 3 times.

The solution was successful and the supplier integrated it into its client offer.

SCOPE

- Design with the supplier: 6 months

- Erection on storage area: 6 months

- Setting up of Air Inlet using a SPMT and a high capacity crane: 1 month

KEY FIGURES

Air Inlet: prefabrication hours

Tonnage air inlet module

Lifting means employed: SPMT and crane

Projects

No Results Found

The page you requested could not be found. Try refining your search, or use the navigation above to locate the post.

Your Ponticelli contact

Eva Lempicki

1 rue Lilienthal - Emerainville - BP 79

77312 Marne-la-Vallée Cedex 2

France

+33 (0)1 64 11 11 64

Contact-us